我公司凭借制作纸制品机械的丰富经验及精湛技术,研制成功具有国内首创技术水平的(平板式)超厚硬纸板生产线(专利产品)。

Our company relies on the manufacture paper product machinery's rich experience and the exquisite technology, develops has the domestic origination technical level successfully(plate type)the ultra thick cardboard production line(proprietary product).

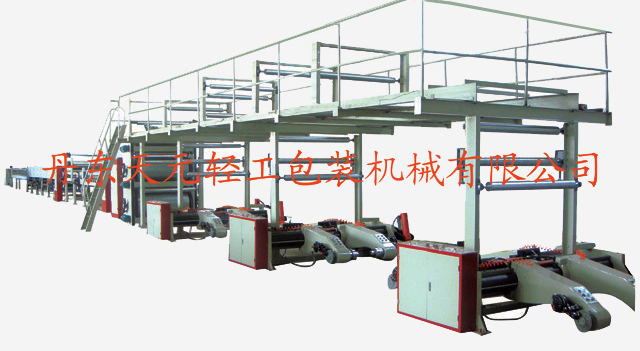

生产线主要由承纸架、过桥输送机、涂胶机、压实机、(平板式)烘干部、冷却部、分纸牵引机、电脑横切机、堆码机等组成,具有生产工艺先进、操作维修方便、安全可靠、节约能源、无环境污染等特点。

Paper production line in order to bearing frame,the bridge conveyor,glue machines,compactors,(flat type)drying department,cooling department,sub-traction machine paper, the computer cross-cutting machine,stacking machine etc.,with advanced production technology,operation and maintenance convenient,safe and reliable,energy saving, no pollution and so on.

生产线采用卷筒纸复合,幅宽有1300mm、1800mm等规格供您选择,可将三、四张原纸进行复合,定量2000g/m2 , 厚度3.5mm, 产量35T—80T/d , 该线生产出的纸板厚度、紧度、水份、平滑度、挺度、抗张强度均达到进口的同类产品,完全可以替代进口的超厚硬纸板,该产品适用于烟箱、酒箱、箱包、食品箱、精装书皮、高档礼品盒、文具用品等。

Production line using reel-paper composite,width are 1300mm,1800mm and other specifications for your choice,can be three or four base paper for complex,quantitative 2000g/m2 ,thickness of 3.5mm,yield 35T-80T/d,the line to produce the cardboard thickness,tightness,moisture,smoothness,stiffness,tensile strenght reached the imports of similar products can replace imported extra-thick cardboard,the product applies to tobacco boxes,wine boxes,boxes bag,food box,hardcover book cover,high-grade gift boxes,stationery,etc.

该生产线弥补了单机手工装裱的多项缺点,大幅度降低了生产成本,提高了产品质量,经济效益可观,是您制作硬纸板及硬纸板箱的理想设备。

The line make up for a number of shortcomings of single-hand wall paper to significantly reduce the production cost and improve product quality,economic benefits were considerable,the production line is the manufacturing cardboard and cardboard boxes of ideal device.